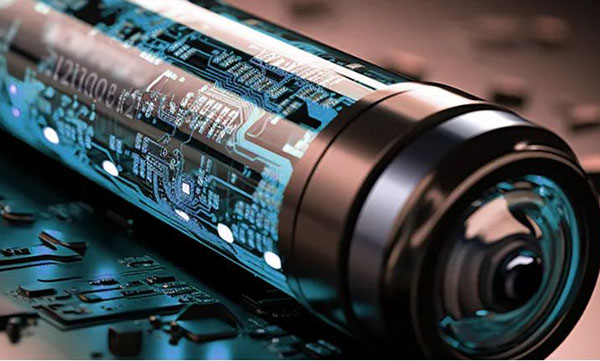

As the "vanguard" of solid-state batteries, the installation process of semi-solid-state batteries is accelerating. According to industry statistics, the installed capacity of domestic semi-solid-state batteries has exceeded 2GWh in the first half of this year . CITIC Securities pointed out that since 2024, China's solid-state battery industry has seen marginal changes such as the launch of semi-solid-state mass-produced models and the penetration rate of semi-solid-state batteries in vehicles reaching 1%, and the signal of industrialization has arrived.

As of now, models such as NIO ET7, SAIC Zhiji L6, Dongfeng E70, Dongfeng Lantu Zhuiguang, and SERES5have been equipped with semi-solid-state batteries . Many car companies such as GAC Aion, Changan Deep Blue, HiPhi, Geely, JAC, and FAW generally plan to install semi-solid-state batteries before 2025.

As for battery manufacturers, many companies including CATL, EVE Energy, Guoxuan High-tech, Farasis Energy, Zhengli New Energy, Lishen Battery, Honeycomb Energy, Xinwoda, BYD Battery, Ganfeng Lithium, and Qingtao Energy have already made arrangements in semi-solid-state battery technology and are accelerating mass production.

Recently, Changxin Technology stated on an investor communication and interaction platform that BYD Power, in which the company holds a stake, has achieved a breakthrough in semi-solid polymer battery technology and has begun external sales. Its semi-solid automotive-grade stacking research and development products are expected to be shipped externally in 2025. Xinwanda also stated that the company's semi-solid battery products have been developed and can be promoted to mass production depending on demand.

In June this year, Farasis Energy’s Guangzhou base was put into trial production with a planned production capacity of 30GWh, marking the completion of Guangzhou’s largest semi-solid-state battery production base . In April this year, Zhengli New Energy released ultra-high nickel semi-solid large cylindrical batteries. In January this year, Lishen Battery announced the completion of the development of semi-solid-state batteries with an energy density of 402Wh/kg.

Prior to this, CATL released a semi-solid condensed state battery; EVE Energy developed a semi-solid state battery based on a 50Ah soft-pack battery, which can achieve an energy density of up to 500Wh/kg ; Honeycomb Energy launched its world's first square semi-solid state battery - the second-generation jelly battery; Guoxuan High-tech also unveiled its semi-solid state battery product with an energy density of 360Wh/kg.

01

The impact of semi-solid-state batteries

" Only through the development stage of semi-solid-state batteries can we achieve the maturity of all-solid-state battery technology, the stability of equipment and the mass production of key materials. Without these, all-solid-state batteries will only be castles in the air," said Li Zheng, co-founder and general manager of Qingtao Energy.

Generally speaking, due to the use of a new structure and material system, the production process of all-solid-state batteries is more complicated and the cost is higher than that of semi-solid-state batteries. Semi-solid-state batteries can, to a certain extent, learn from the production technology and equipment of traditional liquid batteries to reduce production costs and are more conducive to large-scale commercial applications.

Guotai Junan pointed out in a research report that the popularization of solid-state batteries will start with semi-solid batteries and progress step by step. After the technology is stable and the process is determined, the cost will drop, and semi-solid batteries will slowly increase in volume, and then gradually evolve to full-solid-state batteries. The impact of semi-solid batteries on the existing lithium battery industry chain is mainly in the midstream diaphragm and electrolyte links.

However, overall, the semi-solid state will not change much from the existing liquid lithium-ion battery system. The semi-solid state route will still use a diaphragm, and the basic process will not change. Most of its preparation methods will follow the traditional lithium-ion battery process and equipment technology. All-solid-state batteries do not require a diaphragm, but require the cooperation of an electrolyte membrane and a coating process.

"From the perspective of the subsequent development of the industry, liquid batteries and solid-state batteries will coexist for a long time, and there are differences in their application areas. Semi-solid and quasi-solid batteries require the use of diaphragms, while all-solid batteries require a base film as a medium. " Dongfeng New Materials pointed out. Guoxuan High-tech said that the company's all-solid-state Jinshi battery does not require a traditional polymer porous diaphragm, but uses a solid electrolyte membrane as a diaphragm.

02

Semi-solid battery separator technology layout

With the continuous advancement of semi-solid-state battery technology and the promotion of commercial applications, the separator, as one of the key materials of the battery, still has its place. Industry insiders pointed out that compared with liquid batteries, semi-solid-state batteries require the separator to have a larger pore size and higher strength, and usually adopt wet and coating processes.

At present, many manufacturers are planning semi-solid separator products in order to occupy a favorable position in the next round of technological innovation. Enjie Co., Ltd., the leader in separators, said that in terms of semi-solid batteries, the company has cooperated with Beijing Weilan and Liyang Tianmu Pioneer to establish Jiangsu Sanhe, which specializes in the research and development of semi-solid coated separators. At present, the company's special separators suitable for semi-solid batteries have been mass-produced in small batches and supplied to well-known battery manufacturers in the market.

It is understood that the semi-solid electrolyte composite membrane developed by Enjie Co., Ltd. has more outstanding discharge performance in low-temperature environments compared to conventional diaphragm products, especially in ultra-low temperature environments of -30°C, which can increase the discharge capacity retention rate of finished battery cells by more than 10% year-on-year.

Another diaphragm leader, Xingyuan Materials, also stated that the solid electrolyte composite diaphragm developed by the company's R&D team has excellent electrochemical properties, can meet the technical requirements of many leading battery companies and solid-state battery and semi-solid battery manufacturers at home and abroad, has been recognized by customers and is ready for mass production.

Dongfeng New Materials, which crossed over from the printing and packaging industry, said that the company actively cooperates with downstream customers to deploy high-performance, high-safety semi-solid battery separators, solid electrolyte membrane materials and coating processes to accelerate the layout of solid-state batteries and their key materials.

According to Changyang Technology, the company's related wet-process diaphragm products adopt a new semi-dry and semi-wet process . While producing conventional lithium battery diaphragms, it can also produce products with ultra-high porosity. It has currently carried out technical cooperation with many relevant mainstream customers at home and abroad, and has obtained small batch orders from leading customers and many other customers. In the future, the products are expected to achieve technological breakthroughs and applications in the fields of high-power, semi-solid batteries and solid-state batteries.

For a long time, diaphragms have been the category with the highest gross profit margin among the main materials of lithium batteries. Semi-solid battery diaphragms are less disruptive to production lines and processes, so diaphragm manufacturers may still be able to maintain their dominant position. However, with the future development of all-solid-state battery industrialization, it is bound to have a significant impact on the market structure of the diaphragm industry, and the market will also be reshuffled.