In the session theme of SESSION1 "Application and Market Development Trend of Advanced High Power Battery Technology in HEV, Micro Hybrid (48V), UAVs and Electrical Tools", Dr. Mao Huanyu, Chairman of Suzhou Yulang Battery Co., Ltd., gave a keynote speech on "Advantages and Disadvantages of Clyindar 4680 Battery".

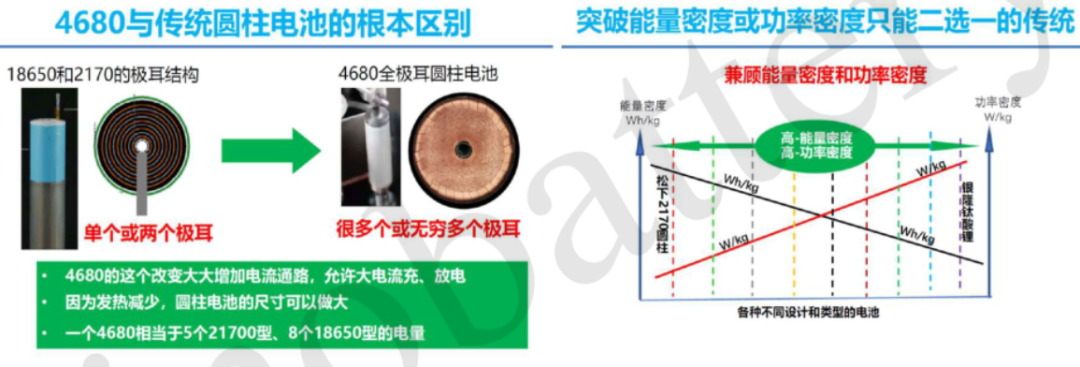

As can be seen from Tesla from 18650 to 21700 to 4680, in fact, it is not only a change of size, but also a significant improvement of internal structure.Unlike the 18650 and 21700, which have one or two poles, the 4680 pole ear becomes an infinite number of poles. This change greatly increases the current path and increases the battery from a high energy density to a high rate. This change allows high current charge and discharge, reduces heat, increases the size of the cylindrical battery, and reduces the cost.A 4680 is equivalent to about five 21700 and eight 18650s.

Let's take a closer look at the typical battery design. On the left is the energy density coordinate, on the right is the power density coordinate, and in the middle is a variety of different designs, such as the Panasonic 2170 and Yinlong's lithium titanate.When the energy density increases, the power density will decrease, or if the power density of lithium titanate battery is very high, but the energy density is relatively low, forming such a scissors difference, now the all-pole ear 4680 out can take into account the high energy density and high power density, so as to break through the limitations of the original cylinder battery.

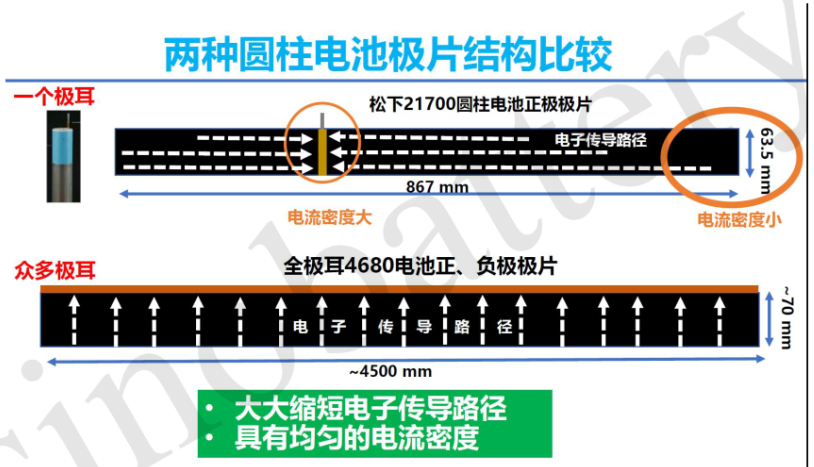

Let's look at the comparison of the two battery structures. The above is the battery used in Panasonic 21700Tesla Model3. There is a pole ear in the middle (not in the middle).If we look at the 4680 full ear cell, the electron conduction path adds up to the width of the pole plate, about 70 millimeters, and it's very uniform.For Panasonic batteries, the current density is very high where the pole ear is located. If you are far away from this place, the current density is very low, so the current density is very uneven.By the way, the 4680 cell we made has a length of 4.5 meters, and it's very difficult to get high power with one or several ears on a very long cell, so that's a fundamental difference.

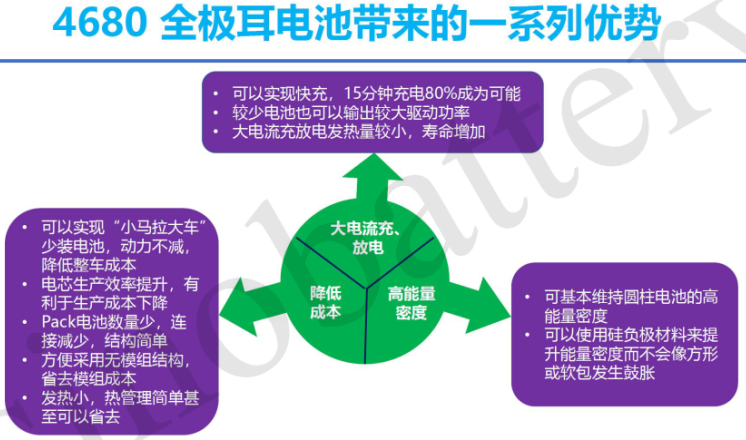

There are two features here. One is that it greatly shortens the electron conduction path.One is to have a uniform current density.This brings a number of advantages:

For example, fast charging can be realized, and 80% charging becomes possible in 15 minutes.Fewer batteries can also output more driving power.High current charge and discharge heat is less, life is increased.Here, for example, Yuliu is now doing three yuan 4680 battery, the charging curve is basically the same, the quick charging performance 0 to 80% only needs 12 minutes and 13 seconds, the rate of discharge pulse mode can reach 8C, the energy density reaches 230Wh/kg.The quick charging performance of the YuluoFeFe4680 is 0 to 80%. It only takes 12 minutes and 30 seconds for the pulse discharge to reach 11C and the energy density to reach 180 Wh /kg.

In terms of reducing costs, some car factories can achieve a small horse car, not so much battery, such as the original 50 degrees of electricity, now with 30 degrees of power with the original is the same, or even bigger, if in some cases, without considering the driving mileage can be less battery.In addition, the efficiency of cell production is also improved, which is conducive to the reduction of production costs.The advantages of PACK are even greater. The structure is very simple, which is important to reduce the cost.In addition, the energy density can also be improved to basically maintain the high energy density of the cylinder battery. At the same time, the cylinder is more suitable to use silicon anode material to improve the energy density.

How could something like this form?We just look at its structure.For example, in the process of electronic conduction, the battery can be divided into two impedances, one is the electronic conduction impedance, the other is the ion conduction impedance.Electrical impedance is the resistance (on the order of a few hundred millimeters) that flows along the foil, and the foil has a very small flow area, just the thickness times the width.Ionic conductivity is the resistance caused by the flow of ions through the gap and membrane between particles of anode and cathode material. The conduction distance is on the order of micron, and the conduction area is very large.In a cell, if the structure is not appropriate, more than 90% of the internal resistance is from the foil resistance, the all-pole ear structure basically eliminates this resistance.

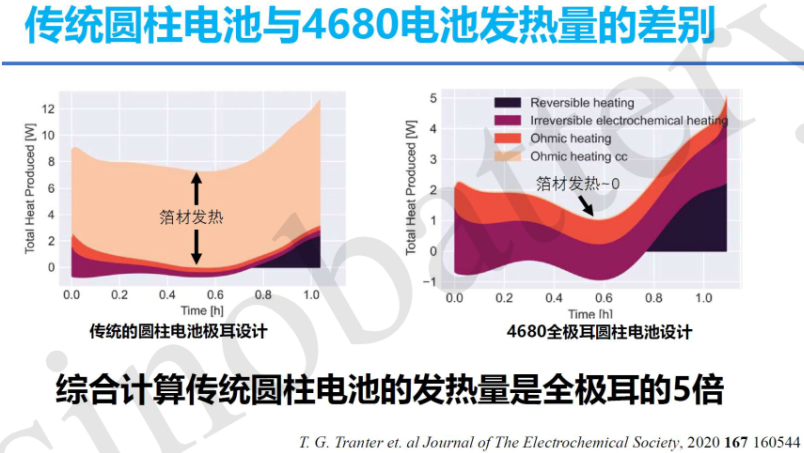

Oxford University of Britain several scholars specifically on 4680 battery simulation, and the traditional cylindrical battery ear design comparison, ABCD is different heat dissipation conditions, see the same heat dissipation conditions, left and right, how much is the temperature difference between it?If we normalize the scale, we can see that the curve is only a little bit here, and the heating temperature is much lower.Let's look at its calorific value, which is also described here. This is the traditional cylinder cell's pole ear design, and the foil has this much calorific value, but basically you can't find it inside the cylinder 4680.The comprehensive calculation of the calorific value of the traditional cylinder battery is more than 5 times that of the full pole ear, so the calorific value is only 20% of the original.

Look at it not only calorification is small, and the distribution is also very uniform, SOC from 90% discharge, the traditional design of the battery center temperature reaches 80 degrees Celsius, but 4680 is very uniform, there is no special hot place, the balance is below 45 degrees Celsius, which is under the same discharge conditions.Uniform heating is an important aspect of extending battery life.Because of the low calorific value and uniformity, the cost of PACK thermal management can be greatly reduced.This is the battery pack inside the Model 3, with more than 4,000 batteries passing through serpentine tubes, and you can tell by looking at it that it's not cheap.Now 4680 has no fever, you can remove all these, removed after what?This is the completely non-modular PACK advertised by Tesla. It is so tightly arranged that a flat plate is added below or above for heat dissipation, which greatly reduces the cost of thermal management.

Let me compare the 4680 to a blade battery.The biggest feature of the blade battery is to save space and increase the utilization rate by 50%. Then, when we are so tightly arranged, we use 53.57kWh battery for comparison, which is 135 A and 396.8V battery pack. The measurement of length, width and thickness shows that the cell space is this value, and the total volume of the cell is 0.143 cubic meters.Similarly, we use spacer cells, each 18 A calculation, requires 930PCOS, forming a square array of 39×24cells, the cell space volume is 0.141 cubic meters, the two are comparable.In addition, the 4680 has its advantages. The pole of the blade battery has a 915 mm electronic conduction path. The 4680 conduction path is only tens of mm, so the 4680 multiplier will have more advantages.

Let's compare the 4680 to the square cell.At present, the size of the lithium iron battery used in Tesla Model 3 is 62mm (thick)x 275mm(wide)x 80(high). We found the capacity and voltage of the battery on the nameplate of the car. The total volume of the battery is 0.147m3 when the battery cells are lined up one by one.Similarly, we use 4680 of 18Ah to form a 40×24 square array. The total volume of the cell is 0.144 cubic meters. Therefore, compared with the square, 4680 has the same volume energy density.

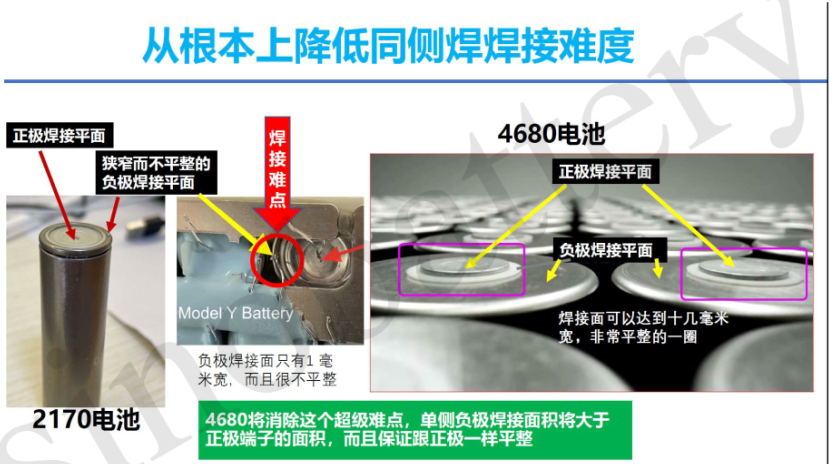

According to Tesla's report, the structure offsets some of the weight.At the same time it has an important factor to reduce the cost, there are two curves here, take a peak place, so the 46mm diameter cost reduction is the largest, the range is also the largest.At least the cost of PACK production has been reduced from 2170 to 4680 cells, from 4416 cells to 960 cells, and welding costs and assembly costs have been significantly reduced.The original aluminum wire welding with the negative electrode of the 2170 battery is a great difficulty, carefully see this place solder joint is very ugly, why so?Mainly because the welding plane provided by the negative electrode is too small, or curved, only about 1 millimeter wide, so it is always bad welding, and the yield of finished products in this place is very low.But changed to 4680 is not the same, the positive welding plane in the middle, the negative welding plane has a dozen millimeters wide, very smooth a large circle.

In terms of energy improvement, because the cylinder is easier to achieve fail-safe, the positive electrode can be made of high nickel material, the cylinder battery can inhibit the expansion of the negative electrode to a certain extent, and the negative electrode can be made of silicon carbon material.In one Tesla Model 3, 4,416 2170 batteries have a surface area of 7.46 square meters, while 960 4,680 batteries have a surface area of 4.55 square meters, reducing the weight of the steel shell by about 40%.

Said so many advantages, then speak a difficult point, is the collection of ear, can see three: kneading ear, cut ear, multi-ear.

Kneading ear is more popular in China, but this way because of the space occupied by the foil, the width of the positive electrode coating is only about 64 mm, and the height of space utilization is only 80%.Like Panasonic's cylinder is 70 mm, but the width of the positive coating is 63.5 mm, and the height of the space utilization rate reaches 90 percent.In addition, the shape of the pole ear is not controlled, and it is easy to short circuit.We think this approach is problematic.In addition, both ends of the manufacturing are closed state, electrolyte infiltration obstruction.

Tesla method is to cut down very ear method, the pole piece is sideways, cut into pieces, then put it a roll of a ear to form spiral of thing, the extrusion would be much better than no rules, for space is small, but at the same time there are still some problems, such as the laser intensity and the focal length is not easy to control, easy to melt through to batteries or no welding on the inside.Also due to the closed situation at both ends, electrolyte infiltration obstruction.Tesla said in the video that continuous production is possible, but at least the injection process is not continuous production.

What about multipole ears?When we look carefully at the diagram, the poles are stacked neatly. In fact, when we do it, we find that this is not easy.As you can see from this formula, this is the polar formula.This S is the position of the pole ear on the pole plate, θ is the Angle, and the constant a is proportional to the thickness.Then, when the number of turns reaches about 50 and the θ value in this formula reaches more than 300, the ratio of S to thickness change is very large. When the thickness of the electrode changes by 1 micron, the position of the pole ear changes by 10,000 times.For example, the plates are aligned without any error in thickness.If both positive and negative have a micron, and then magnify 10,000 times, the error of the pole ear position will reach dozens of millimeters.

So the conclusion is that the all-pole ear 4680 battery is a major breakthrough in the performance of cylindrical batteries, heat reduction, fast charging performance greatly improved.The cost from the cell to the PACK will have a relatively large reduction.Of course, the difficulty lies in the extreme ear collection, but with the progress of technology, will gradually overcome the difficulties, give play to the advantages.